Founded in 2024 at the University of Oregon, biomedical startup company VivoTex seeks to transform tissue engineering through an innovative approach to advanced, microfiber 3D printing using techniques pioneered in the lab of UO professor Paul Dalton.

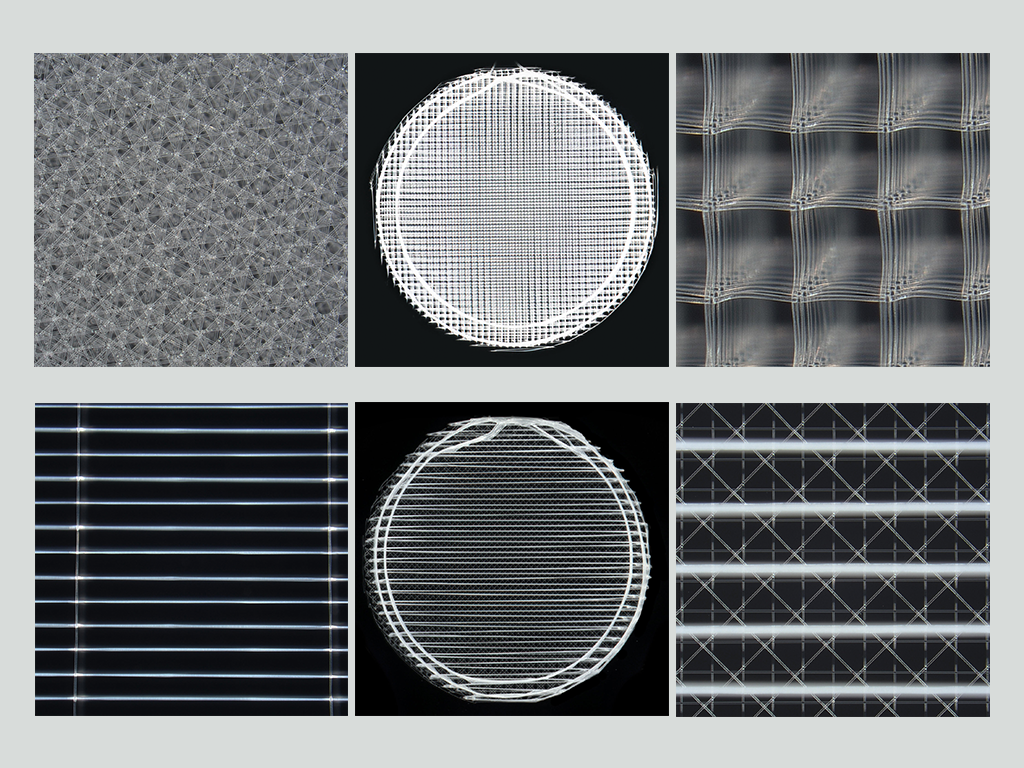

When used to create highly precise and very tiny 3D-printed microfiber scaffolds, melt electrowriting mimics the natural matrix that supports cells in human tissue.

With uses in regenerative medicine, cancer research and drug discovery, the scaffolds accelerate cell growth, enhance cell-to-cell communication, and boost cell viability, improving experiment outcomes, speed, and reproducibility. From bone and nerve grafts to cancer research, the scaffolds hold scientific promise both as research tools and as custom-tailored solutions for clinical applications.

“The potential for melt electrowriting to address medical conditions caused by injury or diseases is truly phenomenal,” Dalton said. “I see this almost every day when a lab in another part of the world publishes a research paper on its use for some type of application.”

To bring the microfiber scaffolds into wider use, Dalton and UO research engineer Ievgenii Liashenko began a partnership with Newberg-based A-dec, a leading dental equipment manufacturer looking to grow in new directions. Translating years of scientific innovation into a commercially available product stands to dramatically change healthcare.

“VivoTex is great example of how the commercialization of a technology nurtured in a university environment enables incredibly impactful research to benefit society,” said Christine Dixon Thiesing, the UO’s associate vice president for industry, innovation and translation.

Thiesing’s office works with faculty members to help them patent intellectual property, license it to third parties and found companies. Liashenko helped ramp up the new technology to industrial scale.

Dalton, the Bradshaw and Holzapfel Research Professor in Transformational Science and Mathematics, moved his lab from Germany to the UO in 2021 in search of an innovation-forward ecosystem. He found that in the Phil and Penny Knight Campus for Accelerating Scientific Impact, where the guiding vision is to shorten the timeline between discovery and societal impact through world-class research, training and entrepreneurship in a nimble scientific enterprise.

Just as the Knight Campus’s founder-friendly approach attracted Dalton to the UO, it was A-dec’s foundational values that gave him confidence in the business partnership.

“What I admire about A-dec are the prominent company values that they aspire to and work for: compassion and community-minded responsibility as well as the need for continuous improvement and mindfulness,” Dalton said.

A recent research collaboration with L'Oréal resulted in the creation of an artificial skin model closely resembling natural human skin. That achievement unlocks the capability to model biological and environmental impacts on skin and the ability to study wound healing, and it does not involve animal experiments or products.

And a serendipitous experiment with fellow UO faculty member Ramesh Jasti, director of the Materials Science Institute, resulted in glowing nanohoops, which are ring-shaped carbon molecules Jasti invented, combined with microfiber scaffolds, which could eventually result in biomedical implants that glow under fluorescent light.

Though a patent is pending and the product still is in early stages of development, the glowing hoops could be used to track and monitor implants inside the body over time, allowing researchers to easily distinguish what’s part of an implant and what is cells or tissue.

“We are excited about the opportunity to launch VivoTex and enable researchers around the world to utilize this cutting-edge technology,” said Chris Adamek, president of VivoTex. “In our market analysis, it was clear that microfiber scaffolds can enable scientific breakthroughs, but the barriers to accessing this technology are high. Our goal is to become the world’s preeminent bio scaffold provider, making this technology more accessible by producing a portfolio of high-quality nano-fiber scaffolds that researchers can easily integrate into their research.”

The technology allows for precise control over the cell microenvironment, allowing researchers to replicate tissue models more effectively than ever before. Partnerships at the UO and with A-dec are the catalyzing force allowing VivoTex to bring that technology to the people who need it.

“Having worked in research development over the past 30 years, I’ve learned that companies like VivoTex are essential for implementing and in translating technologies into widespread practice,” Dalton said. “We will be involved in facilitating these breakthroughs, and I will measure VivoTex’s progress by the number of injuries or diseases that we are able to cure or improve treatments for, rather than pick a specific one.”